No products in the cart.

OEM vs ODM Pencils: What’s the Best Strategy for Your Brand?

- Mark Yang

- June 10, 2025

- 1:55 pm

- No Comments

Table of Contents

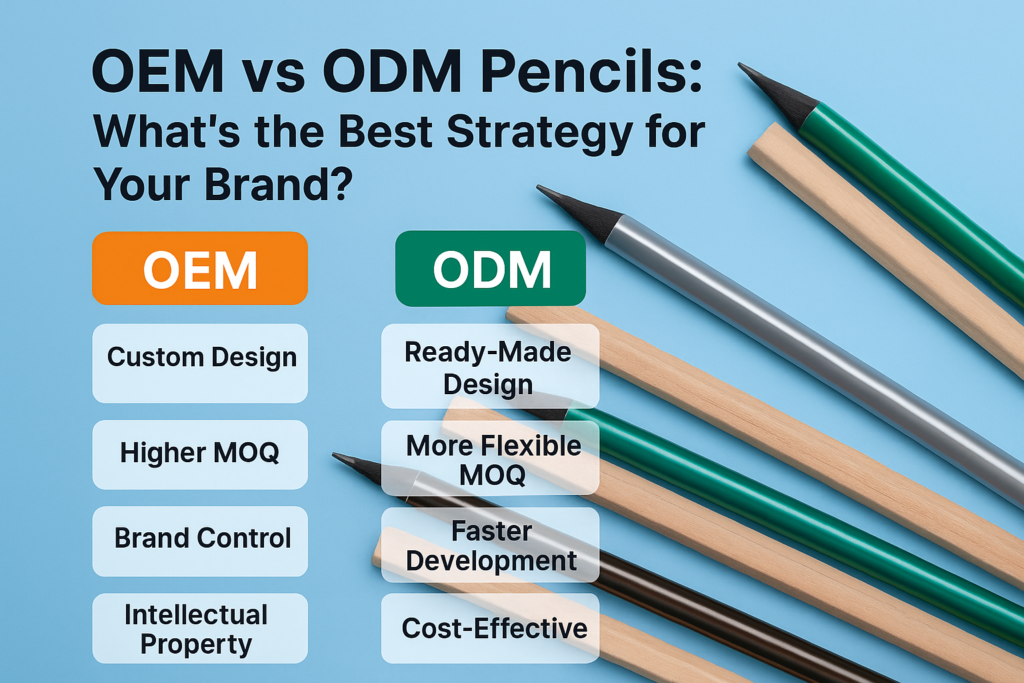

A vibrant display of colored pencils in a retail setting. Choosing between OEM and ODM models will determine how your products are designed and branded. In the stationery industry, European gift distributors and importers face a pivotal choice: use OEM (Original Equipment Manufacturing) or ODM (Original Design Manufacturing) for pencils. OEM means you (the brand) provide the pencil’s design and specifications, and the factory produces exactly what you’ve specified. ODM means the factory has ready-made pencil designs that you rebrand and sell, often with only minor tweaks (like color or logo)datapel.com. This decision affects custom pencil manufacturer Europe sourcing, intellectual property, costs, lead times, and the degree of control you have.

Customization and Creative Control

OEM and ODM differ most in design freedom. With OEM, you have full creative control: you dictate wood type, lead hardness, paint color, barrel shape, ferrule and eraser style, even packaging design. The factory follows your blueprint, ensuring a unique product. For example, an OEM project could produce special-edition Christmas pencils or signature colored pencils with your exact graphics. As one contract manufacturing guide notes, OEM customers “can provide new designs and stipulate extensive specifications… enabling them to create custom products”. In contrast, an ODM stationery solution offers limited customization: you pick a base model from the supplier’s catalog and generally can only request cosmetic changes like paint color, logo imprint, or minor accessories. Bullet points highlight these differences:

- OEM (Full Custom Design): Brand supplies the design concept (molds, artwork, colors). Factory creates tooling and new molds if needed. You can customize virtually every feature – lead type, wood material, barrel shape, eraser style, printing effects, etc..

- ODM (Catalog Rebranding): Manufacturer provides existing pencil designs. You select one and request small changes (e.g. change the imprint color or add your logo). The core product stays the same across buyers. ODM is ideal for bulk personalized pencil supply when a ready-made design meets your needs.

Intellectual Property and Brand Protection

Protecting your designs and brand is critical. In an OEM arrangement, you own the IP for any original design you contribute. The factory merely executes your specifications. As Komaspec explains, “the IP rights to the portion of the design the customer provides belong to them and cannot be used in other products without their express permission”. In other words, you retain full rights to the custom pencil shapes, graphics, and technology you create. Conversely, with an ODM, the supplier “designs, manufactures, and sells specific products… and hold[s] all the IP rights to the products”. The ODM manufacturer’s design is their intellectual property, and you typically only license it by sticking to branding changes.

- OEM – Brand-Owned IP: You keep patents or design rights on your custom pencil. Competitors cannot legally copy your exact design.

- ODM – Manufacturer-Owned IP: The factory may sell the same base pencil to other clients. You have only branding rights (color, logo). To protect exclusivity, negotiate NDA and exclusivity clauses.

Maintaining IP control also ties into quality and exclusivity. OEM products are unique to your brand; ODM products risk appearing in other catalogs unless explicitly restricted. European brands should also register any distinctive pencil designs or logos with the EU Intellectual Property Office. Clear contracts and confidentiality agreements are recommended in both models to prevent unauthorized copying.

Production Cost, MOQ, and Lead Time

Cost structure and order size requirements differ sharply. OEM generally requires a higher up-front investment. You must pay for new tooling, prototypes, and design work. That means higher Cost per Unit initially, though price falls with volume. In contrast, ODM is usually cheaper to start: since the pencil already exists, tooling costs are shared by the manufacturer and other brands. The manufacturer absorbs design and certification costs, giving you a lower initial price. In practical terms:

- Initial Investment: OEM – High. Expect to fund product design, mold creation, and testing. ODM – Low. The factory’s existing designs avoid these costs.

- MOQ (Minimum Order Quantity): OEM pencils are made-to-order, so MOQ is typically medium to high (often thousands or more). ODM pencils have lower MOQs; some factories accept very small orders (even dozens) of standard products, then scale up.

- Lead Time: OEM takes longer upfront (weeks/months of prototyping). ODM is faster, since the product is already developed. Many ODM suppliers stock finished pencils, enabling shorter lead times.

A workspace with financial reports and charts. OEM projects involve higher design costs and tooling (longer lead times), whereas ODM models spread those costs across many clients for quicker delivery.

Example: A brand launching a custom plush pencil gift set might accept the higher OEM cost for unique artwork, while a distributor ordering bulk personalized pencil supply for school giveaways might choose an ODM model to keep prices down and get products faster.

Quality Assurance, Risk and Control

Quality control is a prime concern for B2B buyers. With an OEM pencil factory, you can specify certifications, materials, and testing regimes. For instance, you might require FSC-certified wood, non-toxic paint (CE-compliant), and independent quality inspections. OEM contracts allow you to enforce strict QA benchmarks. ODM products come pre-certified (the supplier’s responsibility), which can save time but means you rely on their standards.

Risk factors also differ: Custom OEM tooling locks you into that manufacturer. If you need to switch suppliers later, reproducing the design elsewhere can be difficult and expensivekomaspec.com. ODM products are generic, so you can often switch factories (since designs are not exclusive to one plant). However, as Komaspec notes, “these [ODM benefits] come at the expense of control, IP rights, and product differentiation”komaspec.com.

- Quality Assurance: OEM – You “have more control over quality assurance, product testing, and certifications”. ODM – Factory’s standard QC applies; verify samples carefully.

- Supplier Dependence: OEM – Custom tooling means you depend on that supplier’s capacity and ethics (BSCI audits recommended). ODM – Products are standardized, so moving production is easier but watch for copycat designs.

- Product Differentiation: OEM yields unique offerings; ODM has limited differentiation. If brand uniqueness and IP are priority, OEM is safer.

Hand pointing at cost charts. Choosing ODM saves cost and time, but OEM provides substantial control and uniqueness.

Use Cases: Gifts, Retail Lines, and Promotions

Which model suits common scenarios for stationery brands and gift distributors? Here are examples:

- Seasonal or Limited-Edition Pencils: OEM is ideal. For instance, a retailer wanting a custom Christmas pencil design (with unique die-cut shape or integrated holiday graphics) should commission an OEM run. The brand can ensure special features (e.g. glitter paint or scented erasers) that ODM won’t offer.

- Branded Retail Lines: If a giftware company or store launches its own pencil brand, OEM lets them build true private-label products. For simpler product lines (e.g. basic colored pencils or promotional golf pencils), ODM catalogs can suffice.

- Corporate Promotions and Giveaways: ODM often wins for straightforward promo pencils. For example, an ODM provider showcases eco-friendly stationery sets (recycled paper pencils, wooden sharpeners) in pre-set bundles. These can be quickly imprinted with a logo. As one case study notes, the factory’s wood pencils can be engraved with a company logo and fitted into branded cases (linen or wooden) for an eco-friendly gift. Such sets are convenient (the unit keeps everything together) and boost brand image as sustainable. OEM could be used if the client needs a novel pencil style or exclusive packaging beyond the ready-made kit.

By matching your strategy to the use case, you balance creativity against convenience and cost. ODM works well for high-volume standard items or mixed stationery kits, while OEM is better for high-impact branded products.

Design Support and Prototyping

Regardless of model, most pencil manufacturers offer design and prototyping support. In an OEM pencil factory, you will typically collaborate with their R&D team. They can help translate your concept into manufacturable designs: creating CAD drawings, producing sample pencils, and adjusting for tooling. For example, suppliers often cite “Personalized Design” services – including mold opening, color customization, and logo placementeagle-stationery.com – as part of their offerings. Likewise, the pencil supply chain commonly advertises services like R&D, design, sampling, manufacturing, and QCinterwell.cn.

- Prototyping: Expect to review prototype samples (hand-sharpened or wax models) and refine artwork before mass production.

- Technical Expertise: Good manufacturers advise on technical details (e.g. optimal wood species, clay/graphite ratio for leads, lacquer type).

ODM vendors also often assist with minor customization. If you choose an ODM stationery solution, you can work with their in-house designers to tweak colors, packaging text, or slight design elements. The pre-made nature means fewer iterations, but you still get proof sheets or digital mock-ups to approve.

Working with a factory that provides comprehensive design support (often highlighted in their service offerings) can speed development and ensure your pencils look and feel right before large-scale production

Manufacturing Workflow

Pencil production involves several steps, whether OEM or ODM:

- Material Preparation: Cedar or other softwood panels are cut into slats. Graphite is mixed with clay to form “lead” cores.

- Core Insertion: The lead cores are placed between two wood slats, glued, and pressed. The sandwich is cut through to create pencil halves with embedded leads.

- Shaping and Curing: Slats are shaped (hexagonal, round, etc.), sanded smooth, and baked/dried to harden.

- Finishing: Pencils are lacquered (for smooth finish and branding). Custom artwork, laser engravings, or foil stamps are applied per design.

- Assembly: Metal ferrules and erasers are attached if required.

- Quality Check: Manufacturers perform QC tests (checking lead break resistance, finish quality, safety of materials).

- Packaging: Pencils are packed in boxes, sleeves, or sets as specified.

OEM projects add extra design steps (creating custom molds or packaging prototypes). ODM production skips those, using standard molds and assembly processes. As one supplier notes, they provide full “Samples & Prototyping, Manufacturing & Warehousing, [and] Quality Control” to clientsinterwell.cn. Ultimately, both models follow these core workflows; the difference lies in whether the design is brand-new or pre-existing.

Packaging and Branding

Custom packaging is a key branding opportunity. You can choose from: card sleeves, sliding boxes, tins, tubes, or gift pouches. OEM projects usually involve fully custom packaging – for example, a luxury gift box printed with your artwork. ODM providers also offer some packaging customization; as cited on a major supplier site: “Customized Packaging… including boxed bags, gift boxes, etc.”.

Options include:

- Individual Boxing: Single pencils in printed sleeves or tubes (great for giveaways).

- Sets and Kits: Multiple pencils in a hinged or slide-out box (good for retail or corporate gifts).

- Eco Packaging: Recycled cardboard cases, wooden gift boxes, linen pouches (appealing to eco-conscious clients)theodmgroup.com.

- Branding Prints: Logo and branding can be printed or embossed on both pencils and boxes. For example, an eco stationery set featured wooden pencils and a linen case – the wood pencils were engraved with logos and the case embroidered.

A flat lay of color charts and pencils. Packaging can be fully tailored (branded boxes, gift-ready sets) to enhance your product’s appeal, as manufacturers offer “personalized packaging design” services.

EU regulations should guide materials: use FSC-certified wood for pencils and ensure any inks or coatings meet CE/REACH standards. Work with your supplier to develop packaging that protects pencils in transit (especially by sea freight) and resonates with your market.

Conclusion and Next Steps

Choosing between an OEM pencil factory and an ODM stationery supplier depends on your brand’s priorities. OEM is best when you need unique products, full IP control, and are willing to invest in design and tooling. ODM is smart for faster turnaround and lower cost, using ready-made designs with minimal changes. Both models require due diligence: ensure your manufacturer meets EU certifications (FSC, CE, etc.) and offers the support you need. For example, leading suppliers hold FSC and CE certifications to comply with European market standards.

Assess your order volume, budget, design complexity, and IP requirements. Create a clear specification (for OEM) or select the best-fit existing design (for ODM). Use bullet-point lists above to compare the factors: customization, cost, MOQ, timeline, and IP ownership.

Ready to get started? Contact us to explore OEM and ODM pencil solutions tailored to your market. We can connect you with experienced pencil manufacturers (whether local or overseas) that fit your brand’s strategy and ensure a smooth supply of custom pencils for European distributors.

Key Takeaways: A custom pencil manufacturer in Europe or overseas OEM pencil factory will produce exactly your design (maximizing brand control and IP), while an ODM stationery solution offers off-the-shelf designs you can rebrand at lower cost. Consider bulk personalized pencil supply needs – OEM for exclusive items, ODM for standard promotional runs – to choose the best path for your brand.

Share This Post

Share on facebook

Share on twitter

Share on linkedin