No products in the cart.

How Factories Produce Sharpened vs Unsharpened Pencils

- Mark Yang

- January 5, 2026

- 3:53 pm

- No Comments

Table of Contents

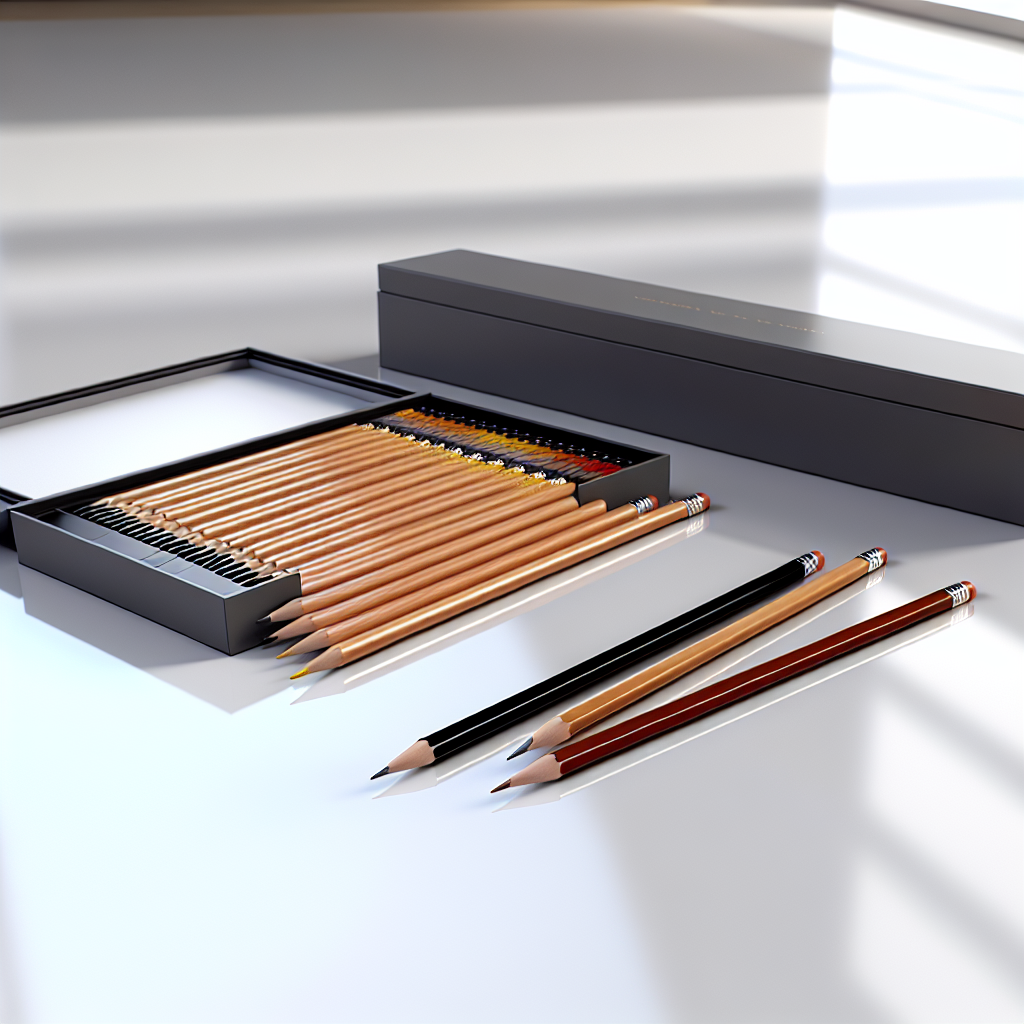

Walk into any classroom, art studio, or office supply store, and you’re bound to find a familiar tool: the humble pencil. But behind this everyday item lies a surprisingly complex manufacturing process—especially when it comes to deciding whether a pencil leaves the factory sharpened or unsharpened. For brands, retailers, and OEM buyers, this distinction isn’t just cosmetic. It impacts packaging, usability, and even logistics. In this article, we’ll explore how factories produce sharpened vs unsharpened pencils OEM, unpack the technical processes involved, and reveal what this means for end users and manufacturers alike.

Why the Sharpened vs Unsharpened Debate Matters

At first glance, the difference between a sharpened and an unsharpened pencil seems trivial. But from a manufacturing and supply chain perspective, it’s a significant decision point. Sharpened pencils are ready to use out of the box, offering convenience to consumers. Unsharpened pencils, on the other hand, are often preferred for bulk packaging, longer shelf life, and lower risk of damage during transit.

For OEM (Original Equipment Manufacturer) clients—such as schools, promotional product companies, and stationery brands—this choice affects production timelines, pricing, branding opportunities, and even user satisfaction. Understanding the factory processes behind each type can help buyers make more informed procurement decisions.

From Timber to Tool: A Brief Overview of Pencil Manufacturing

The journey of a pencil begins with wood—typically incense cedar or basswood—chosen for its softness, straight grain, and ease of sharpening. According to HowStuffWorks, the wood is cut into thin slats, dried, and then grooved down the center to hold the graphite core. This core is a mixture of graphite and clay, precisely engineered to determine the pencil’s hardness grade (e.g., HB, 2B, etc.).

Once the leads are inserted, another grooved slat is glued on top, forming a sandwich. These composite boards are then cut into individual pencils, shaped (typically hexagonal or round), painted, and stamped with branding. This is the point where the production process diverges based on whether the pencils will be sharpened before packaging.

How Factories Produce Sharpened Pencils

Sharpened pencils require an additional step after shaping and finishing. This involves automated sharpening machines that use rotating blades or abrasive wheels to carve the familiar conical point. But it’s not as simple as running a pencil through a sharpener. Factories must account for:

- Lead durability: Softer leads (like 4B or colored pencils) are prone to breakage during sharpening.

- Wood grain consistency: Uneven wood can splinter or cause irregular sharpening.

- Sharpening angle: A standard angle (typically 23–26 degrees) ensures consistent performance and aesthetic.

To ensure quality, manufacturers conduct sharpenability testing. As explained in a Durzerd Pencil article, this involves testing pencils across multiple sharpener types to evaluate resistance to breakage, smoothness of cut, and point retention. These tests are especially important for colored pencils, which contain wax-based cores that can crumble easily.

Once sharpened, pencils are inspected for tip uniformity and lead centering—both critical for user satisfaction. They’re then packed in trays or boxes with protective inserts to prevent tip damage during shipping.

Why Some Pencils Are Left Unsharpened

Unsharpened pencils skip the sharpening stage entirely, going straight from shaping and finishing to packaging. This approach offers several advantages:

- Reduced production cost: Eliminating sharpening saves time and equipment wear.

- Lower shipping risk: No fragile tips means less chance of breakage in transit.

- Better for bulk orders: Schools and offices often prefer unsharpened pencils for long-term storage and distribution.

Unsharpened pencils also allow end users to customize their sharpening angle. Artists, for example, may prefer a longer taper or a chisel point—something not achievable with factory-sharpened pencils. Additionally, OEM clients often choose unsharpened pencils for promotional use, as they offer more surface area for branding and are easier to print on before final sharpening.

OEM Considerations: Which Option Fits Your Brand?

Whether you’re sourcing pencils for resale, branding, or educational use, choosing between sharpened and unsharpened formats involves several factors. Here’s a breakdown:

| Criteria | Sharpened Pencils | Unsharpened Pencils |

|---|---|---|

| Consumer Convenience | High – ready to use | Low – requires sharpening |

| Shipping Durability | Moderate – tips can break | High – no fragile tips |

| Branding Surface Area | Reduced due to taper | Full barrel available |

| Production Cost | Higher – extra sharpening step | Lower – fewer steps |

| Customization Potential | Limited | High – user-defined sharpening |

Sharpening Technology in Modern Factories

Advanced pencil manufacturers invest in high-speed sharpening machines capable of processing thousands of pencils per hour. These machines use precision-calibrated blades to ensure uniform tips and minimal lead breakage. Some even feature sensors that detect off-center leads and reject defective units before they reach packaging.

For colored pencils, which are notoriously fragile, factories often use slower-speed sharpeners with gentler abrasive wheels. These machines are designed to reduce torque and vibration, which can crack the soft wax-based cores.

In OEM contracts, clients can often specify the sharpening style they prefer: standard cone, long point, or even specialty shapes for cosmetic pencils. This level of customization adds value but also complexity to the production process.

Packaging Strategies: Protecting the Point

Once pencils are sharpened, packaging becomes a critical concern. Exposed tips are vulnerable to breakage, especially during bulk shipping. Common solutions include:

- Plastic tip protectors: Small caps that shield the point during transit.

- Foam inserts: Used in premium packaging to hold pencils in place.

- Tiered trays: Stagger pencils to prevent tips from touching each other.

Unsharpened pencils, in contrast, can be packed more densely and with less protective material, reducing packaging waste and shipping volume—important considerations for eco-conscious brands.

Environmental and Sustainability Factors

Sharpening pencils at the factory generates waste—wood shavings and graphite dust—that must be collected and disposed of responsibly. While many factories recycle these byproducts, the additional energy and materials used in sharpening can increase the product’s carbon footprint.

Unsharpened pencils, by avoiding this step, are sometimes favored in sustainability-focused procurement policies. OEM buyers looking to minimize environmental impact may consider this when placing large orders.

Final Thoughts: Aligning Product Type with Purpose

Choosing between sharpened vs unsharpened pencils OEM is more than a matter of appearance. It’s a strategic decision that affects usability, branding, cost, and sustainability. For quick-turn retail products or classroom-ready supplies, sharpened pencils offer convenience. For promotional campaigns, artistic use, or large-scale distribution, unsharpened pencils provide flexibility and durability.

By understanding the manufacturing processes—from graphite formulation to sharpening techniques—you can better align your product specifications with your business goals. And whether you’re sourcing from a local workshop or a high-volume overseas factory, clarity on these options will help you get the most value from your OEM pencil partnership.

For more insights on pencil production and quality testing, explore this guide to sharpenability testing or dive into the full HowStuffWorks breakdown of pencil manufacturing.

Related Reading

Share This Post

Share on facebook

Share on twitter

Share on linkedin